Our Product

Product Feature

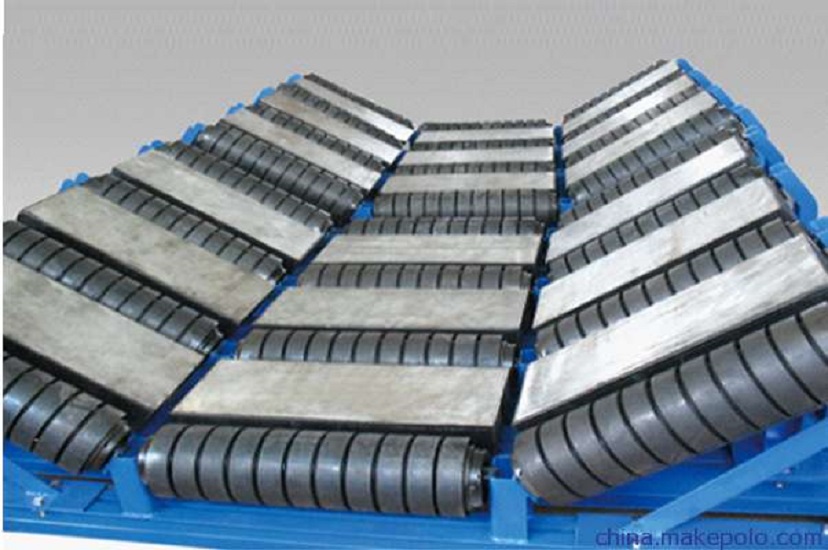

Buffer bed is mainly used to replace buffer roller. Buffer bed is made up of buffer strip. Buffer strip is mainly made up of buffer strip. Buffer strip mainly uses excellent high elasticity special rubber layer to absorb the impact force when material falls, which greatly reduces the impact on conveyor belt when material falls, and really improves the stress condition of blanking point. The friction coefficient between conveyor belt and buffer strip is lowest and the wear resistance is good by using special UHMW polyethylene surface. The use of buffer bed ensures the contact between the conveyor belt and the surface, and the force is uniform. It effectively prevents the longitudinal tearing of the belt caused by the breaking and shedding of the idler. At the same time, it greatly reduces the probability of the longitudinal tearing of the belt after it is penetrated by sharp or sharp materials.

Product Feature

Buffer bed product characteristics:1. No moving parts, reduce daily maintenance costs. 2. Absorbing shock energy. 3. The inclined chamfer can guide the belt smoothly and avoid tripping. 4. Suitable for all kinds of belt width and angle; can withstand strong impact. 5. Installation is fast and simple, and easy to check and update. 6. The device and the blanking point of the conveyor belt can prolong the service life of the belt.

Buffer bed product advantages:1. Surface contact between buffer strip and conveyor belt effectively prevents damage to conveyor belt. 2. The conveyor belt is loaded uniformly at the discharge port, which greatly reduces the daily repair and maintenance costs. 3. Effectively eliminate material spatter and leakage caused by non-uniform force on conveyor belt. 4. The smooth surface of UHMWPE reduces the friction of conveyor belt to the lowest level.5. The arc design of the polyethylene layer surface ensures the smooth and smooth operation of the conveyor belt. 6. Ultra-high elastic special rubber layer can absorb the material impact to the maximum extent. 7. The parts of the buffer strip are connected by hot vulcanization process, which is compact and firm. 8. The design of the bottom steel structure makes disassembly and assembly convenient and fast.The advantages of buffer bed in all aspects determine that it is the development trend of traditional roller support.

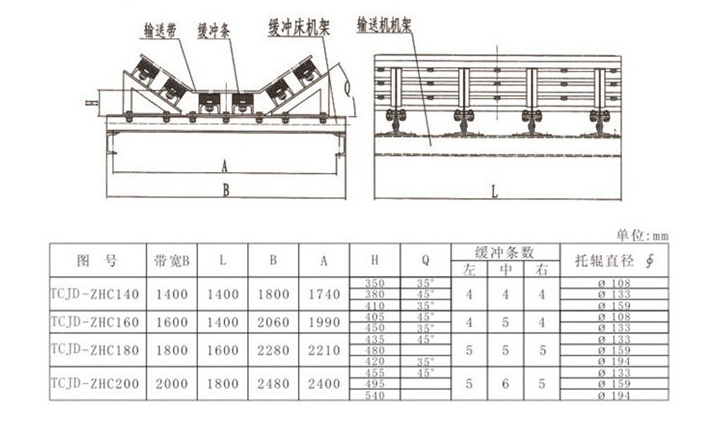

Adaptation Range of Heavy Buffer Bed

Buffer Bar SpecificationAdjustable range of slot angle buffer bed

Buffer Bar Specification